How to Get Started

Think carefully about the requirements of your job. You should have a general idea about your needs, including dimensions, materials, etc. The Machine Shop is capable of making and modifying a wide variety of parts and instruments from various materials, including metals, wood, ceramics, plastics, etc. Postdocs should consult with their supervisors with any questions before approaching the machine shop.

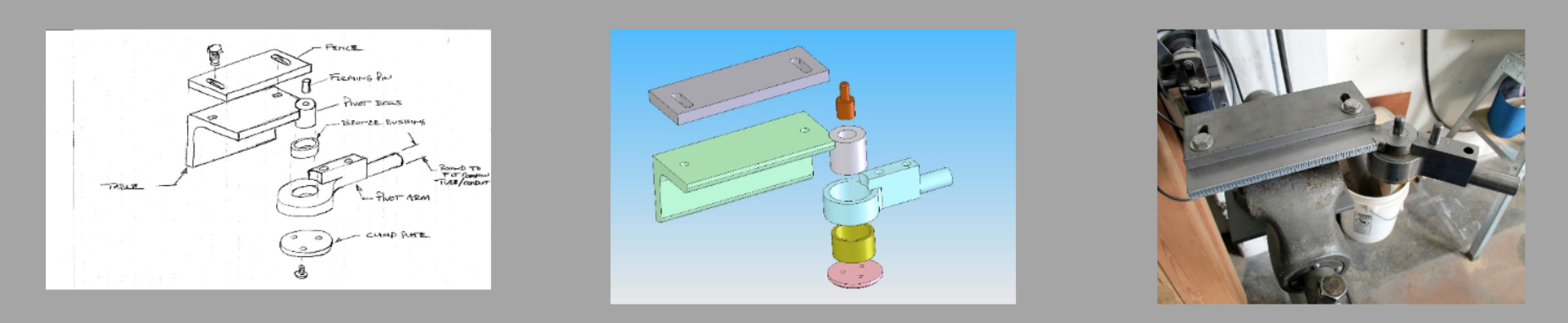

Once you have a basic plan, schedule a time to discuss your design with the shop. The material requirements, possible job‐specific costs (tools, materials, outsourcing, etc.), and time frame should all be discussed. The shop may make specific suggestions to your design to help facilitate the fabrication process.

Formal requests should include drawings or sketches with dimensions (both standard and metric are fine), materials, time frame and any other detailed instructions. Be specific if a job requires tight tolerances, special finishing, or heat treatment. If you bring your own materials, be sure to include the Materials Safety Data Sheet.

You'll need to be connected to the VPN to submit a ticket.

Submit a ticketOur Machines

We maintain a modern machine shop with state-of-the-art CNC capabilities.

New in 2020, this new CNC works on four axes, which allows the machine to both turn and mill materials at the same time.

The Tormach 8 tool is a CNC lathe with vise and collet holder

The AgieCharmilles CUT 200 Wire EDM

AgieCharmilles Drill 20 Hole Popper

Matsuura ES-550V 30-tool-holder vertical machining center with 15,000 RPM spindle

Okamoto OGM 250 UDX cylindrical external / internal grinding machine.

Okamoto 820 Surface Grinder

Miller Syncrowave 350 LX TIG welder